Carrier 17/19EX Handbücher

Bedienungsanleitungen und Benutzerhandbücher für Nein Carrier 17/19EX.

Wir stellen 2 PDF-Handbücher Carrier 17/19EX zum kostenlosen herunterladen nach Dokumenttypen zur Verfügung Bedienerhandbuch, Spezifikationen

Inhaltsverzeichnis

Contents

10

Introduction

36

Figure 4

41

Summary

44

Details

45

Details (See

48

Figure 6

48

Starters

50

Controls

50

Figure 18

63

Figure 19

67

Figure 20

71

Deadband

75

Shunt Trip

80

Oil Cooler

86

Load Balancing

103

To Log Off

112

Figure 24

113

Local Start-Up

118

CONTROL

121

Safety Shutdown

124

Inspect Wiring

139

0- 900 500

142

901- 7000 1000

142

7001-14500 2500

142

Check Starter

147

Oil Charge

150

Software Version

151

Initial Start-Up

166

TARGET GUIDE

167

VANE POSITION

167

Cooler-Condenser

178

Utility Vessel

178

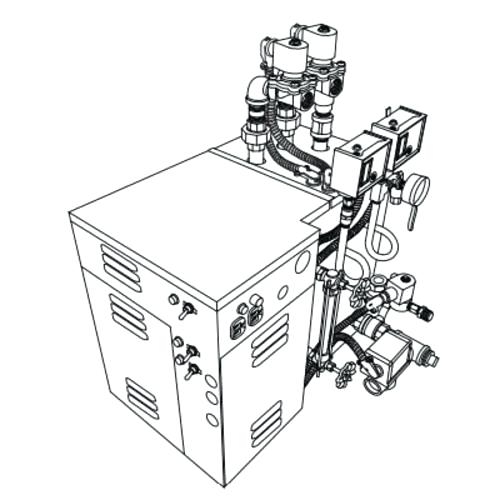

Pumpout System

178

Preparation

187

C C CCCCC

190

CC CCCCC

192

C CC CCCC C

193

Condition

194

Leak Rate

197

Figure 35

199

Figure 36

201

Handle carefully

202

Measurement

211

Adjustment

213

Final Alignment

217

Doweling

220

Oil Changes

226

Procedure

229

Cleanliness

231

Sleeve Bearings

235

Condenser

247

Figure 47

252

Resistance Check

256

Voltage Drop

256

Figure 48

261

Control Test

264

Control Modules

267

Green LEDs

268

Other Green LED

269

Green LED

269

(Continued)

316

(Page 1 of 2)

333

(English)

336

Motor End View

355

(Status01)

371

INSTRUCTIONS

426

Weitere Produkte und Handbücher für Nein Carrier

| Modelle | Dokumententyp |

|---|---|

| 30GTN |

Spezifikationen

Carrier 30GTN Specifications,

96 Seiten

Carrier 30GTN Specifications,

96 Seiten

|

| 16JB |

Bedienungsanleitung

Carrier 16JB Product data,

28 Seiten

Carrier 16JB Product data,

28 Seiten

|

| 69NT40-511-1 |

Wartungshandbuch

Carrier 69NT40-511-1 Service manual,

116 Seiten

Carrier 69NT40-511-1 Service manual,

116 Seiten

|

| 8DF-13 |

Spezifikationen

Carrier 8DF-13 Specifications,

15 Seiten

Carrier 8DF-13 Specifications,

15 Seiten

|

| AQUASNAP MPW015-045 |

Spezifikationen

Carrier AQUASNAP MPW015-045 Specifications [en] ,

20 Seiten

Carrier AQUASNAP MPW015-045 Specifications [en] ,

20 Seiten

|

| 19CB |

Anleitung zur Fehlerbehebung

Carrier 19CB Troubleshooting guide,

14 Seiten

Carrier 19CB Troubleshooting guide,

14 Seiten

|

| FLOTRONIC II 30GN040-420 |

Spezifikationen

Carrier FLOTRONIC II 30GN040-420 Specifications,

88 Seiten

Carrier FLOTRONIC II 30GN040-420 Specifications,

88 Seiten

|

| HS070-160 |

Bedienungsanleitung

Installation Instructions,

8 Seiten

Installation Instructions,

8 Seiten

|

| 19EF |

Spezifikationen

Carrier 19EF Specifications,

72 Seiten

Carrier 19EF Specifications,

72 Seiten

|

| GTR040-420 |

Spezifikationen

Carrier GTR040-420 Specifications,

104 Seiten

Carrier GTR040-420 Specifications,

104 Seiten

|

| 69NT40--541--200 TO 299 |

Bedienungsanleitung

69NT40--541--200 to 299,

83 Seiten

69NT40--541--200 to 299,

83 Seiten

|

| FLOTRONIC II 30GN040-420 |

Betriebsanleitung

Carrier FLOTRONIC II 30GN040-420 Operating instructions [en] ,

72 Seiten

Carrier FLOTRONIC II 30GN040-420 Operating instructions [en] ,

72 Seiten

|

| 38EYG |

Bedienungsanleitung

38EYG Puron® Cube Heat Pump 024-060 Single,

4 Seiten

38EYG Puron® Cube Heat Pump 024-060 Single,

4 Seiten

|

| 69NT40--541--200 TO 299 |

Wartungshandbuch

Carrier 69NT40--541--200 TO 299 Service manual,

112 Seiten

Carrier 69NT40--541--200 TO 299 Service manual,

112 Seiten

|

| AQUASNAP MPW015-045 |

Spezifikationen

Carrier AQUASNAP MPW015-045 Specifications,

20 Seiten

Carrier AQUASNAP MPW015-045 Specifications,

20 Seiten

|

| HXC076-186 |

Spezifikationen

Carrier HXC076-186 Specifications,

140 Seiten

Carrier HXC076-186 Specifications,

140 Seiten

|

| 58DFA |

Betriebsanleitung

Carrier 58DFA Operating instructions,

14 Seiten

Carrier 58DFA Operating instructions,

14 Seiten

|

| 50PG03-07 |

Bedienungsanleitung

48PGD/E/F/K/L/M03-07 50PG03-07,

8 Seiten

48PGD/E/F/K/L/M03-07 50PG03-07,

8 Seiten

|

| 30HW018-040 |

Spezifikationen

Carrier 30HW018-040 Specifications,

8 Seiten

Carrier 30HW018-040 Specifications,

8 Seiten

|

| PH61 |

Bedienungsanleitung

Model PH61 - Kappus Company [en] ,

2 Seiten

Model PH61 - Kappus Company [en] ,

2 Seiten

|